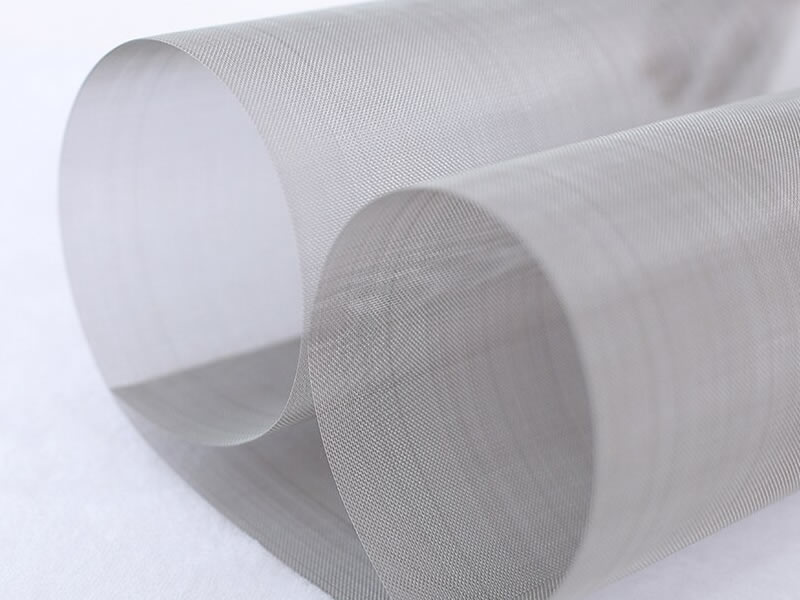

Dutch Weave Stainless Steel Mesh-Dutch Twill Weave and Dutch Plain Weave

Unveiling our high-precision Dutch weave stainless steel mesh, Weihao Co. showcases a product uniquely characterized by its dual-diameter wire weaving technique. Providing varied mesh opening sizes by using thicker warp wires and thinner weft wires, we curate a product that's seamlessly suited to diverse applications, balancing fine particle filtration and efficient fluid flow.

Dutch weave stainless steel mesh employs two wire diameters, featuring thicker, closely spaced warp wires and thinner, widely spaced weft wires, creating a dense mesh with varying opening sizes. Often used in high-precision filtration and separation applications due to its fine particle retention and efficient liquid/gas flow capabilities, it's ideal for situations demanding both filtration and high flow rates. Offering excellent corrosion resistance, durability, and strength, this mesh withstands harsh conditions and chemical exposure, ensuring suitability for applications prioritizing longevity and corrosion resistance. Mesh size and openings can be tailored to application needs, with available grades such as 304, 316, and 316L offering varied corrosion resistance and strength. Commonly used in the petrochemical, pharmaceutical, food processing, and oil and gas industries, Dutch weave mesh assures reliable, precise filtration.

Specifications

Meticulous in our approach, every strand and weave in our stainless steel mesh adheres to stringent specifications. Our offerings vary in wire diameters, mesh counts, and opening sizes, tailored to meet the particular demands of our esteemed clientele, ensuring accuracy and consistency in every square inch.

-

Wire Diameter: Our mesh is fabricated using wires of various diameters, typically ranging from 0.02mm to 2.03mm, subject to the requirement of filtration and application specifics.

-

Mesh Count: With a mesh count range extending from 12x64mesh to 325x2300mesh, we furnish solutions apt for intricate to robust applications, ensuring our meshes are compatible with a multitude of industrial needs.

-

Weave Type: The Dutch weave in stainless steel wire mesh comes in two primary forms: Dutch Plain Weave and Dutch Twill Weave. Both types employ distinctive weaving patterns and offer unique properties that cater to various industrial applications.

In a Dutch Plain Weave, the warp wires are typically thicker, closer together, and run lengthwise in the mesh, while the weft wires (crosswise wires) are thinner and spaced further apart. This kind of weave provides a fine mesh with small, rectangular openings that allows finer filtration due to the dense arrangement of the wires. Specifics about Dutch Plain Weave include:

-

Weaving Pattern: Alternates a single weft wire over and under each warp wire.

-

Mesh Count: Characteristically has a higher number of finer weft wires crossed with fewer, coarser warp wires.

-

Key Features: High tensile strength, exceptional filtration capabilities, and resistance to high pressure.

-

Applications: Predominantly used in separation and filtration applications in the chemical, pharmaceutical, and food and beverage industries, given its capability to retain fine particles.

Dutch Twill Weave employs a twill weaving pattern that adds an extra degree of robustness and stability to the mesh. The weft wires pass over two and under two warp wires, providing a secure and stable structure. Notable aspects of Dutch Twill Weave include:

-

Weaving Pattern: Utilizes a twill weaving technique where each weft wire passes over two and under two warp wires.

-

Mesh Count: Features a consistent mesh count in both warp and weft directions, with a notably tighter weave as compared to its plain counterpart.

-

Key Features: Known for its sturdy structure, enhanced stability, and finer mesh openings.

-

Applications: Widely employed in applications where enhanced filtration precision and improved wear-resistance are crucial, such as in pressure filters for fuel and hydraulic fluid, and in the petrochemical and aerospace industries.

-

-

Opening Size: The aperture size of our mesh varies, with precise openings crafted to enable efficient particle filtration, ensuring optimal performance ranging from micro to macro-scale applications.

-

Tolerance: Accuracy being paramount, our products ensure a strict tolerance level of ±3% to maintain consistency in mesh integrity and performance throughout its dimensional span.

-

Roll Width and Length: Adapting to your project requirements, our mesh is available in standard and custom widths and lengths, facilitating a fit that seamlessly integrates into diverse application environments.

Use

Synthesizing strength and precision, our mesh finds its use across several industries such as petrochemical, pharmaceutical, food processing, and oil and gas, effectively navigating the labyrinth of filtration, separation, and shielding applications.

Advantages and Features

The unique weaving technique provides a dense yet flexible mesh surface, ensuring remarkable particle retention and efficient fluid dynamics. Coupled with excellent corrosion resistance, our mesh stands as a stalwart for durability, strength, and optimal functionality.

Package, Transport

Ensuring the impeccable quality of our mesh is preserved from our doors to yours, Weihao Co. employs secure packaging and reliable transportation methods. Adhering to international shipping standards and protocols, we ensure that our products reach you in pristine condition, regardless of distance or destination.

Popular Specifications of Dutch Plain Stainless Steel Wire Mesh:

Specification Table 1:

| Mesh Count Warp x Weft | Wire Dia mm Warp x Weft | Wire Dia inch Warp x Weft | Micron Rating |

| 8 x 85 | 0.360 x 0.320 | 0.0140 x 0.0125 | 320-340 |

| 12 x 64 | 0.580 x 0.420 | 0.0230 x 0.0165 | 265-285 |

| 14 x 88 | 0.500 x 0.350 | 0.0200 x 0.0140 | 215-235 |

| 24 x 100 | 0.350 x 0.250 | 0.0140 x 0.0100 | 115-125 |

| 30 x 150 | 0.230 x 0.180 | 0.0090 x 0.0071 | 95-100 |

| 40 x 200 | 0.180 x 0.140 | 0.0070 x 0.0055 | 70-75 |

| 50 x 250 | 0.140 x 0.114 | 0.0055 x 0.0045 | 55-60 |

| 80 x 400 | 0.125 x 0.071 | 0.0050 x 0.0028 | 40-45 |

Specification Table 2:

Stainless Steel Wire Cloth (Dutch Plain Weave) | ||||

| Mesh | Wire Diameter (d0) | Aperture | ||

| Vertical | Horizontal | Vertical | Horizontal | Microns |

| 12 | 64 | 0.62 | 0.42 | 270-290 |

| 14 | 80 | 0.50 | 0.30 | 220-240 |

| 24 | 110 | 0.38 | 0.25 | 115-125 |

| 30 | 160 | 0.23 | 0.18 | 95-100 |

| 40 | 200 | 0.18 | 0.14 | 70-75 |

| 50 | 250 | 0.14 | 0.11 | 60-63 |

Dutch Twill Woven Wire Mesh, Made of Stainless Steel:

Table 1:

| Mesh Count Warp x Weft | Wire Dia mm Warp x Weft | Wire Dia inch Warp x Weft | Micron Rating |

| 20 x 250 | 0.250 x 0.215 | 0.0100 x 0.0085 | 70-90 |

| 40 x 400 | 0.180 x 0.140 | 0.0071 x 0.0055 | 90-110 |

| 50 x 500 | 0.140 x 0.114 | 0.0055 x 0.0045 | 70-90 |

| 50 x 600 | 0.140 x 0.090 | 0.0055 x 0.0035 | 60-70 |

| 80 x 700 | 0.100 x 0.080 | 0.0040 x 0.0032 | 45-55 |

| 100 x 800 | 0.100 x 0.070 | 0.0040 x 0.0028 | 36-38 |

| 120 x 1000 | 0.080 x 0.053 | 0.0031 x 0.0021 | 27-29 |

| 165 x 800 | 0.070 x 0.053 | 0.0027 x 0.0021 | 24-26 |

| 165 x 1450 | 0.070 x 0.040 | 0.0027 x 0.0016 | 16-18 |

| 270 x 2000 | 0.350 x 0.028 | 0.0014 x 0.0011 | 9-10 |

| 325 x 2400 | 0.035 x 0.025 | 0.0014 x 0.0010 | 4-5 |

Table 2:

Stainless Steel Wire Cloth (Dutch Twill Weave) | ||||

| Mesh | Wire Diameter (d) | Aperture | ||

| Vertical | Horizontal | Vertical | Horizontal | Microns |

| 20 | 250 | 0.25 | 0.23 | 110-120 |

| 32 | 360 | 0.23 | 0.15 | 100-110 |

| 40 | 400 | 0.18 | 0.14 | 90-110 |

| 50 | 500 | 0.14 | 0.11 | 70-90 |

| 50 | 600 | 0.14 | 0.09 | 60-70 |

| 80 | 800 | 0.12 | 0.07 | 45-65 |

| 165 | 800 | 0.07 | 0.05 | 24-26 |

| 120 | 1000 | 0.08 | 0.055 | 27-28 |

| 165 | 1450 | 0.07 | 0.04 | 16-18 |

| 325 | 2300 | 0.038 | 0.025 | 8-9 |