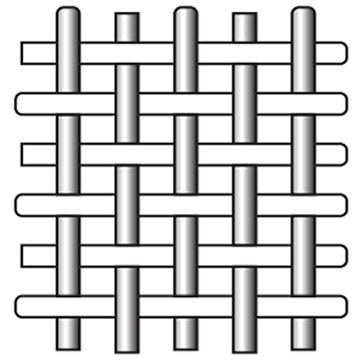

Plain Weave Wire Mesh

Plain square mesh is the most common weave with the same number and diameter of warp and shute wires woven in a simple over and under pattern.

Plain square mesh is the most common weave with the same number and diameter of warp and shute wires woven in a simple over and under pattern.

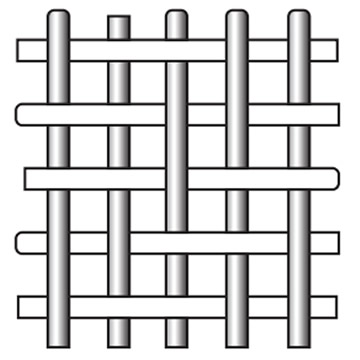

Twill Weave Wire Mesh allows for the use of relatively heavier wires in a specific mesh count compared to plain weave mesh, supporting larger loads.

Dutch weave mesh is mainly used for filtering and separating liquid products. These are arranged very close together to form a zero-mesh structure.

Crimped wire mesh is fabricated from carbon iron wire, galvanized wire, stainless steel wire, or copper wires. All the wires are pre-crimped using a mold before being woven together. It is used for screening in mines, coal factories.

Stainless steel welded mesh is utilized as fencing panels and guards. SS 316 welded mesh is suitable for marine construction projects, while powder-coated SS welded mesh hardware cloth is primarily used for securing windows.

Stainless steel filter elements consist of five layers of 316 mesh, sintered together to form an integrated porous element. These elements are recommended for filtering heavily contaminated gases, liquids, polymers, and steam.

Woven wire mesh is versatile, used for filtering, screening, fencing, and more. The weaving pattern influences the mesh's strength, flexibility, and filtration efficiency. Popular weave types include Plain Weave, Twill Weave, Dutch Weave, Dutch Twill Weave, Reverse Dutch Weave, and Five Heddle Weave. Each type serves specific applications or industries, significantly impacting the mesh's functionality and performance in its intended use.

01.

01.

In this weaving style, each weft wire passes over and under alternating warp wires, and each warp wire passes over and under alternating weft wires.

02.

02.

In this Weave pattern, each weft wire passes over two and under two warp wires, and each warp wire follows suit over and under two weft wires.

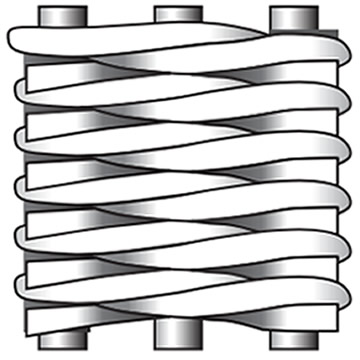

03.

03.

The weft and warp wires interlace in an over-two and under-two pattern, with the intersections of the warp wire inverting at a set distance, achieving a rigid, stable, and robust mesh.

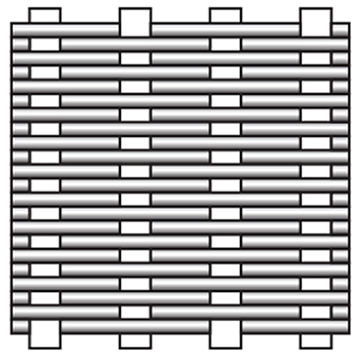

04.

04.

Reverse Dutch weave is applied for optimizing filtering media manufacture thanks to a high percentage crossing/opening surface. Filtering ratings from 14 to 100 microns can be obtained.

Please leave us a message and we will get back to you shortly.