Stainless Steel Filters General Classification

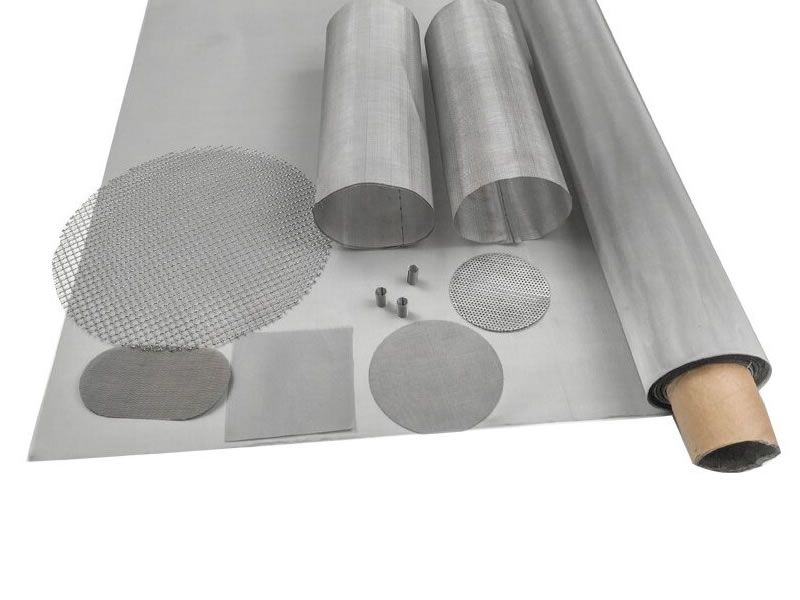

Stainless steel filter is a type of filter made from stainless steel material. It is designed to remove impurities and particles from liquids or gases, ensuring a cleaner and higher quality output. Stainless steel filters offer several advantages, including excellent corrosion resistance, durability, and high temperature resistance. They are commonly used in various industries such as food and beverage, pharmaceutical, chemical processing, oil and gas, and water treatment.

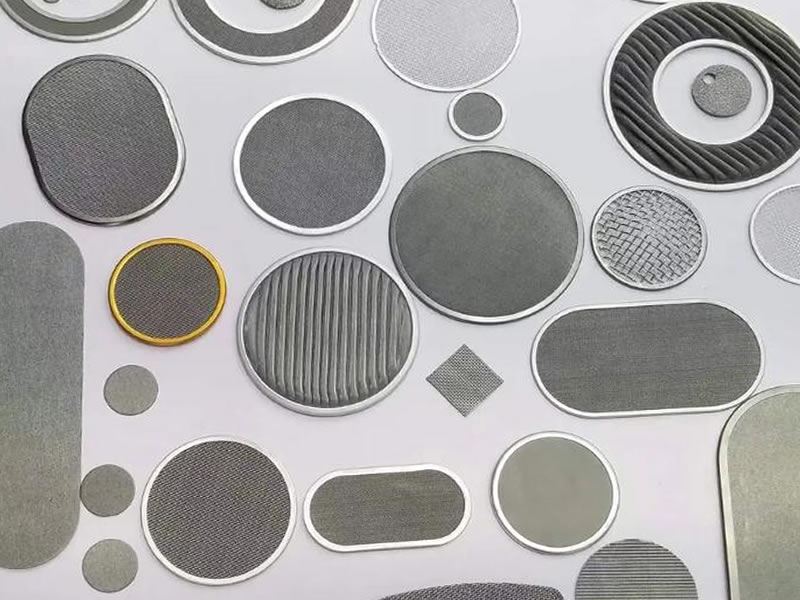

Stainless steel filters can be customized to meet specific filtration requirements and are available in different shapes, sizes, and filtration levels. They are known for their long lifespan and low maintenance requirements, making them a popular choice for applications that require reliable and efficient filtration.

Stainless steel filter cartridge is a type of filtration device that is made from stainless steel material. It is designed to remove impurities and particles from liquids or gases, providing a clean and purified output. Stainless steel filter cartridges offer several advantages, including excellent corrosion resistance, durability, and high-temperature resistance. They are commonly used in various industries such as food and beverage, pharmaceutical, chemical processing, oil and gas, and water treatment.

Stainless steel filter cartridges are typically cylindrical in shape and consist of a perforated outer shell or support structure with a filter medium inside. The filter medium can be made of various materials such as woven wire mesh, sintered mesh, or pleated metal mesh. Stainless steel filter cartridges can be customized to meet specific filtration requirements, including different levels of filtration fineness or micron ratings.

Stainless steel filters are widely used in various industries due to their durability, resistance to corrosion, and ability to withstand various conditions. They can be classified based on several factors, such as structure, application, weaving style, and filtration precision.

Below is a general classification of stainless steel filters:

Based on Structure:

- Wire Mesh Filters: Comprise of woven wire mesh, often used in straining or separating solid particles from fluids.

- Pleated Filters: Utilize a pleated design to increase the surface area, enhancing the filtration capacity.

- Cartridge Filters: Designed as cartridges that can be inserted into filtration systems, typically used in liquid filtration.

- Bag Filters: Consist of a filter bag placed inside a supporting cage, commonly used for filtering large volumes of high-viscosity liquids.

- Disk Filters: Constructed as disks and utilized to filter particles in various applications, like coffee brewing.

- Sintered Filters: Made by fusing together stainless steel particles to create a porous medium, suitable for precision filtration.

Based on Application:

- Industrial Filters: Used in various industries for processes like chemical manufacturing, petroleum processing, and more.

- Medical Filters: Utilized in medical and pharmaceutical applications for sterilization and precision filtration.

- Water Treatment Filters: Employed in water treatment plants for purifying and treating water.

- Food & Beverage Filters: Used in food processing industries to ensure product purity and safety.

Based on Weaving Style:

- Plain Weave Filters: Feature a simple over-and-under weaving style, suitable for standard filtration needs.

- Twill Weave Filters: Incorporate a pattern of diagonal parallel ribs, providing better strength and allowing the use of heavier wires.

- Dutch Weave Filters: Employ a combination of larger warp wires and smaller shute wires, facilitating fine filtration.

Based on Filtration Precision:

- Coarse Filters: Employed for applications where larger particles need to be filtered out.

- Medium Filters: Suitable for applications that require a moderate level of filtration precision.

- Fine Filters: Used for precision filtration where small particles must be separated.

Based on Shape:

- Circular Filters: Often used in applications like coffee filtering or other fluid filtration applications.

- Rectangular Filters: Commonly used in industrial processes where larger surface areas need filtration.

- Cylindrical Filters: Utilized in cartridge filter applications, especially in fluid processing industries.

Based on Filter Media:

- Single-Layer Filters: Comprising a single layer of woven wire mesh, suitable for basic filtration applications.

- Multi-Layer Filters: Involving multiple layers of woven mesh or different media to enhance filtration capability.

- Composite Filters: Combine different materials or types of media to achieve specific filtration characteristics.