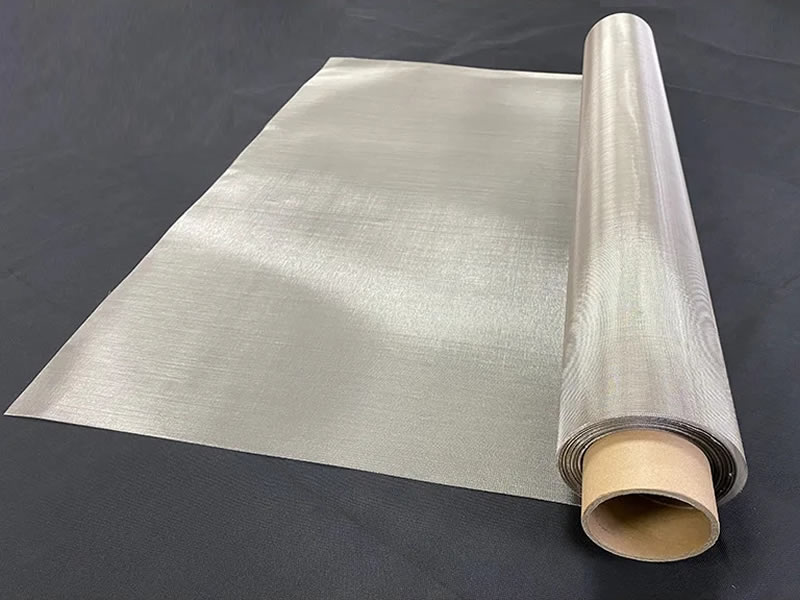

Twilled Weave Stainless Steel Wire Mesh Specifications

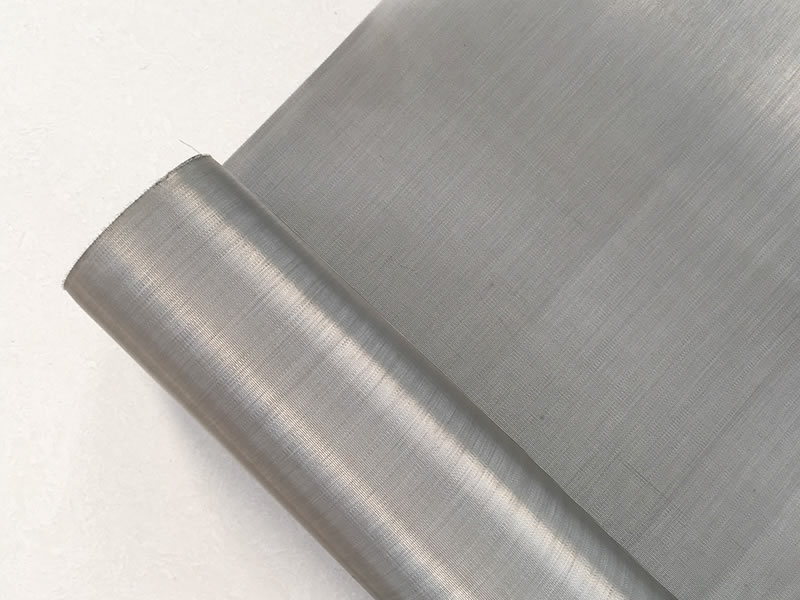

Twilled weave stainless steel mesh, recognized for its diagonal pattern created by the interlacing of warp and weft wires, involves each weft wire navigating over and under two or more warp wires. This weave style enhances strength and filtration capabilities relative to plain weave mesh, accommodating applications demanding elevated strength, filtration precision, and mechanical stability. Its tight mesh structure and diagonal pattern amplify support and pressure resistance, rendering it optimal for rigorous filtration, sieving, and separation processes. Esteemed for its superb corrosion resistance, durability, and resilience against harsh environments, high temperatures, and chemicals, this mesh aligns with applications prioritizing durability and longevity.

With variable mesh size options and availability in various stainless steel grades, such as 304, 316, and 316L, twilled weave mesh serves diverse industries including mining, oil and gas, food processing, and pharmaceuticals, addressing needs for meticulous filtration and mechanical stability.

Specifications:

- Weave Pattern: Twilled Weave

- Each weft wire passes sequentially over and under two or more warp wires, forming a characteristic diagonal pattern.

- The process can be reversed—each warp wire passes over and under two weft wires, depending on specification requirements.

- Wire Diameter:

- Can range from very fine to thick wires, depending on the application.

- Fine wires will yield a higher mesh count (more wires per inch) and are typically used for finer filtration applications.

- Mesh Count:

- Generally ranges between 20 and 500 meshes, though extremes can be manufactured based on specific applications.

- A higher mesh count allows for finer particle filtration but reduces the mesh's permeability and open area.

- Material Grade:

- Commonly used stainless steel grades include 304, 316, and 316L, each conferring distinct corrosion resistance and strength properties.

- 304: General-purpose steel with good corrosion resistance.

- 316/316L: Higher corrosion and chemical resistance, suitable for harsher environments.

- Opening Size:

- Varies depending on wire diameter and mesh count, and can be customized based on filtration requirements.

- Openings can be square or rectangular, depending on the wire diameters used in warp and weft directions.

- Roll Width and Length:

- Typically available in standard roll widths of 36", 40", 48", 60", and can be customized.

- Roll length can also be tailored to specific customer requirements to minimize wastage and joinings in applications.

- Tolerance:

- Stringent tolerances are adhered to during manufacturing, ensuring consistent opening sizes and wire diameters throughout the mesh.

- Tolerances can be especially critical in applications requiring precise particle separation and sizing.

- Finish:

- Can be delivered in a mill finish, or with post-weave finishes such as passivation or ultrasonic cleaning to enhance corrosion resistance or remove contaminants.

- Edge Preparation:

- Available in raw (sheared) edge, salvaged edge, or with an added binding, depending on the application and installation requirements.

Specification of Twill Woven Wire Mesh in Stainless Steel:

| Mesh Count Warp x Weft | Wire Dia mm | Wire Dia inch | Aperture mm | Aperture inch | Micron Rating |

| 100 x 100 | 0.1250 | 0.0049 | 0.1295 | 0.0051 | 130 |

| 120 x 120 | 0.0939 | 0.0037 | 0.1168 | 0.0046 | 117 |

| 165 x 165 | 0.0482 | 0.0019 | 0.1041 | 0.0041 | 104 |

| 200 x 200 | 0.0584 | 0.0023 | 0.0685 | 0.0027 | 68 |

| 250 x 250 | 0.0533 | 0.0021 | 0.0482 | 0.0019 | 48 |

| 300 x 300 | 0.0355 | 0.0014 | 0.0482 | 0.0019 | 48 |

| 300 x 300 | 0.0400 | 0.0016 | 0.0431 | 0.0017 | 45 |

| 325 x 325 | 0.0355 | 0.0014 | 0.0406 | 0.0016 | 41 |

| 350 x 350 | 0.0304 | 0.0012 | 0.0431 | 0.0017 | 43 |

| 400 x 400 | 0.0304 | 0.0012 | 0.0330 | 0.0013 | 33 |

| 500 x 500 | 0.0254 | 0.0010 | 0.0253 | 0.0010 | 25 |

Through careful consideration of the above specifications, twilled weave stainless steel mesh can be accurately designed and manufactured to meet specific industry requirements, ensuring optimal performance in filtration and separation processes, as well as other diverse applications across a multitude of sectors. Always ensure that specifications are comprehensively discussed with Weihao Co., specialists to affirm compatibility with the intended application.

Applications

Twilled weave stainless steel wire mesh, known for its robustness and advanced filtration capabilities, enjoys widespread application across various industries due to its enhanced structural stability and precision filtration qualities.

- Pharmaceutical Industry: Used in filtering, straining, and sieving applications where high precision and purity are paramount.

- Oil and Gas Sector: Plays a crucial role in filtering impurities from extracted materials and protecting equipment by trapping abrasive particles.

- Oil Filters: Utilized in oil filtration systems to prevent contaminants from impairing engine performance.

- Air Filters: Employs in air filtration systems to obstruct debris while maintaining optimal airflow.

- Sifting Flour and Grains: Essential in the sifting processes to segregate materials and prevent contaminants.

- Straining Liquids: Effective in straining unwanted particles from liquids, ensuring purity and quality.

- Particle Separation: Facilitates the isolation of specific particles from chemical compounds.

- Catalyst Filtration: Ensures only pure substances interact in critical reactions.

- Wastewater Treatment: Prominent in treating wastewater by effectively separating solid particles from liquids.

- Air Filtration: Used in various air filtration systems to control pollutants and purify air.

- Reinforcement: Utilized in construction materials as a reinforcing element to enhance structural integrity.

- Protective Guards: Implements in construction sites as protective guards to prevent the entry of larger debris into sensitive areas.