Woven Wire Mesh: Crimp and Weave Styles

1. Woven Wire Cloth Crimp Styles

Pre-crimping, often found in coarser wire cloth or space cloth, facilitates the nesting of warp and shute wires. This action restricts random movement and ensures consistent opening size, thereby adding strength and rigidity to the wire cloth.

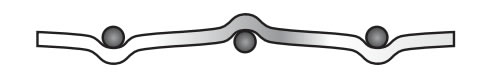

Lock Crimp: Made to hold accurate openings. Each intersection is formed with straight sectionsof fill wires woven within straight sections of warp wires. Fill wires are woven in an alternatingpattern, top and bottom.

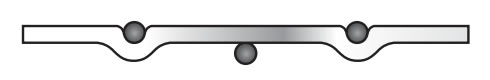

Double Crimp: Square pattern wire cloth using warp and fill wires of equal size. Warp wirespass over and under fill wires in an alternating pattern at adjacent intersections.

Intercrimp: Crimped warp wires filled at every other crimp with fill wires. Provides superiorrigidity and greater stability. Popular for screens and architectural uses.

Flat Top: All crimping is offset to one side producing a single plan on the top which allows for thesmooth flow of materials over the surface.

2. Wire Mesh Weave Styles

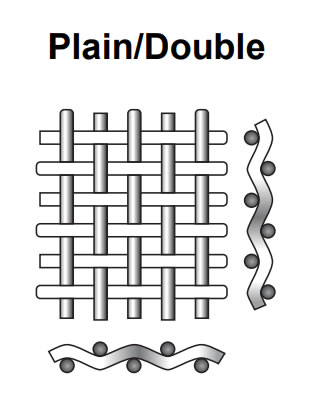

Plain/Double: A widely-used, straightforward weave creating square openings with equal wire sizes in both directions. Warp wires alternatively pass over and under fill wires at perpendicular angles.

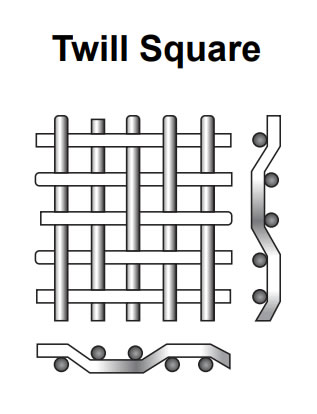

Twill Square: Woven alternately over two and under two warp wires, each warp and shute wire presents parallel diagonal lines. This method accommodates heavier wires for particular mesh counts, allowing for greater loads and finer filtration than plain weave wire cloth.

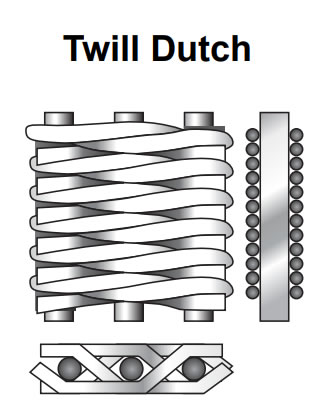

Twill Dutch: A sturdier filter cloth than regular Dutch weaves, it incorporates more wires in a given area. Each shute wire typically interweaves over two warp wires and under two, forming square openings. This weave generally offers finer mesh counts and lower flow, with capabilities to filter particles as minute as 2 microns in diameter.

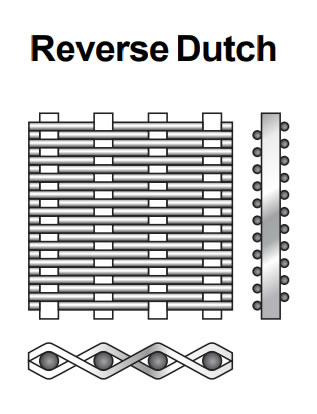

Reverse Plain Dutch: A variation of the filter cloth where the larger wire count is in the warp and the smaller in the shute, inversely to the method used in plain and twilled Dutch weaves. The slimmer warp wires touch each other, while the denser shute wires are tightly woven together.

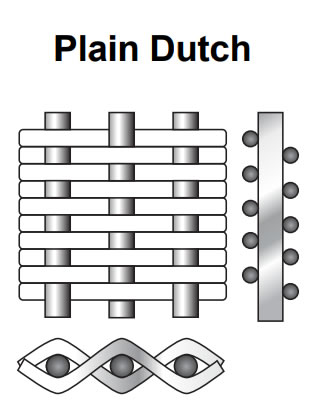

Plain Dutch: Used predominantly as a filter cloth, the openings subtly slant diagonally through the cloth and are not directly visible. This weave employs a coarser mesh and wire in the shute direction, resulting in a compact, firm mesh with significant strength.

Previous: What are the remarkable characteristics of stainless steel mesh?